Top Chemical Raw Materials Manufacturer Insights and Tips?

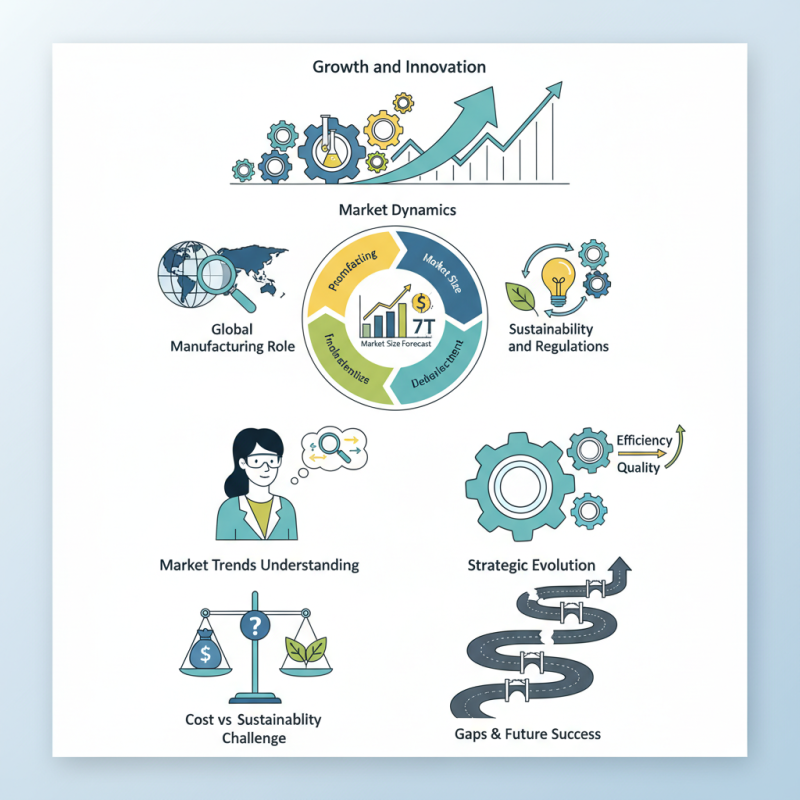

The chemical raw materials industry plays a crucial role in global manufacturing. Research from MarketsandMarkets indicates that the market size for chemical raw materials is expected to reach $7 trillion by 2025. This growth highlights the significance of quality and innovation in producing these essential materials.

Industry expert Dr. Emily Zhang states, "Understanding market trends is vital for a successful chemical raw materials manufacturer." Her insights stress the need for manufacturers to adapt to changes in consumer demands and environmental regulations. The challenge lies in balancing cost and sustainability. Oftentimes, companies focus too much on profits and overlook potential improvements.

In this competitive landscape, manufacturers must evolve. They need to prioritize research and development. The right strategies can lead to breakthroughs in efficiency and product quality. Yet, there are many who struggle to keep up. Recognizing these gaps is essential for future success.

Overview of Top Chemical Raw Materials Manufacturers

The chemical raw materials manufacturing sector is dynamic and vital. Many manufacturers focus on creating high-quality materials for various industries. They produce everything from solvents to intermediates. Each type serves a unique purpose. Understanding this landscape is important for businesses seeking effective partnerships.

When choosing a manufacturer, examine their quality control processes. A strong emphasis on safety and consistency is crucial. Talk to industry peers. Gather their experiences to inform your decisions. Remember, reliability can vary. It’s not just about price; it’s about value.

A tip for navigating this sector: always request samples before ordering in bulk. Testing materials ensures they meet your standards. Engaging with manufacturers directly can yield insights. Don’t shy away from asking tough questions. Their willingness to provide answers can reveal their commitment to quality. This approach can help prevent critical issues later on. Embrace a proactive mindset in your partnerships.

Top Chemical Raw Materials Manufacturer Insights and Tips

| Manufacturer Location | Product Type | Annual Production Volume (tons) | Market Focus | Sustainability Practices |

|---|---|---|---|---|

| North America | Solvents | 50000 | Automotive and Aerospace | Recycling and Reducing Emissions |

| Europe | Polymers | 75000 | Construction and Packaging | Biodegradable Options |

| Asia | Chemical Intermediates | 90000 | Pharmaceuticals | Water Conservation Techniques |

| South America | Agricultural Chemicals | 30000 | Farming | Integrated Pest Management |

| Africa | Explosives | 20000 | Mining | Safety and Compliance Training |

Key Factors Contributing to Success in Chemical Manufacturing

Success in chemical manufacturing hinges on several key factors. One significant element is the efficiency of the production process. According to recent reports, companies that optimize their production lines can increase output by up to 25%. This requires investment in modern technology and machinery, which can be a double-edged sword. While it leads to higher efficiency, initial costs can be burdensome.

Another critical factor is the supply chain management. In a volatile market, ensuring a steady supply of raw materials is essential. Data indicates that around 40% of chemical manufacturers struggle with disruptions in their supply chains. This can lead to production halts, costing companies significant revenue. Effective risk assessment methods should be prioritized to mitigate these challenges.

Lastly, workforce skill levels play a vital role in maintaining competitive advantage. Many manufacturers face skills gaps among employees, affecting overall productivity. Industry surveys show that companies with well-trained staff are 30% more likely to innovate successfully. Investing in continuous education and training programs may lead to obstacles, but the long-term benefits are undeniable. Balancing costs and gains remains a complex issue for many.

Innovative Trends in Chemical Raw Materials Production

Innovative trends in chemical raw materials production are transforming the industry landscape. Many manufacturers are now focusing on sustainability. They seek to reduce waste and energy consumption. This shift improves their carbon footprint. However, adopting new methods can be challenging and costly.

Emerging technologies play a crucial role. For example, bioplastics are gaining traction. They offer an eco-friendly alternative to traditional materials. Additionally, companies are investing in advanced analytics and automation. These innovations streamline production processes and enhance efficiency. Still, the transition isn't seamless for everyone. Some companies struggle to adapt.

As the market evolves, collaboration becomes vital. Sharing knowledge between manufacturers can lead to better solutions. It's important to remain open to feedback. Continuous improvement should be the goal. Engaging with new ideas, while reflecting on past practices, can drive innovation forward. Being agile and responsive to changes will set companies apart in this competitive sector.

Top Chemical Raw Materials Insights

Best Practices for Sourcing and Quality Control in Chemicals

Sourcing chemical raw materials requires careful consideration and strategic planning. According to the American Chemistry Council, 75% of manufacturers report their biggest challenge is maintaining quality. Companies must prioritize quality control throughout the sourcing process. Effective sourcing can lead to significant cost reduction and efficiency improvements.

Quality control starts with supplier selection. Consider suppliers with established certifications. The ISO 9001 standard ensures quality management systems are in place. Regular audits should not be overlooked. A study by the International Journal of Production Research highlights that companies conducting supplier assessments experience 30% fewer defects. It's essential to continuously monitor each supplier's performance.

Chemical properties can vary widely. Variations can impact product consistency. Inconsistent quality leads to production delays. Many companies risk relying too heavily on one supplier. Diversifying sources can mitigate this risk. Investing in real-time quality monitoring systems can provide immediate feedback. This allows more agile responses to issues, reducing waste and improving overall production efficiency.

Market Challenges and Opportunities for Chemical Manufacturers

Chemical manufacturers face various market challenges today. Economic fluctuations often lead to uncertainty. Prices for raw materials can spike unexpectedly. This unpredictability complicates budgeting and financial planning. Manufacturers must navigate these rough waters with agility and foresight. Adapting to changing regulatory environments is also essential. Compliance can be costly and time-consuming. Companies need to invest in training and systems to stay ahead.

Despite these challenges, opportunities abound. The push for sustainable practices is growing. Many consumers favor eco-friendly products. This shift creates a demand for greener chemicals. Manufacturers can innovate by developing sustainable alternatives. Collaborations with research institutions can be beneficial. They allow for shared knowledge and resources. However, not all companies can pivot quickly. Some may struggle with outdated processes. They must reflect on their approaches to remain competitive. The market rewards those who adapt and improve.